ever evolving. For its client’s Salt Cavern

Program, Rangeland designed a chain of

connected salt caverns. Having completed

work on 25 salt caverns over the past few

years, Daye said, “We probably do more

cavern work in Western Canada than any

of our competitors.”

Ethylene is a technically challenging prod-

uct that can be dangerous if handled with

improper care and Rangelanders have

been involved in a number of ethylene-re-

lated projects, like the Redwater Ethylene

Injection Site. This project entailed the use

of technology for compressing and treating

the substance for storage in salt caverns.

Rangeland was one of the few companies

in Alberta to have worked on this technol-

ogy in the past 20 years.

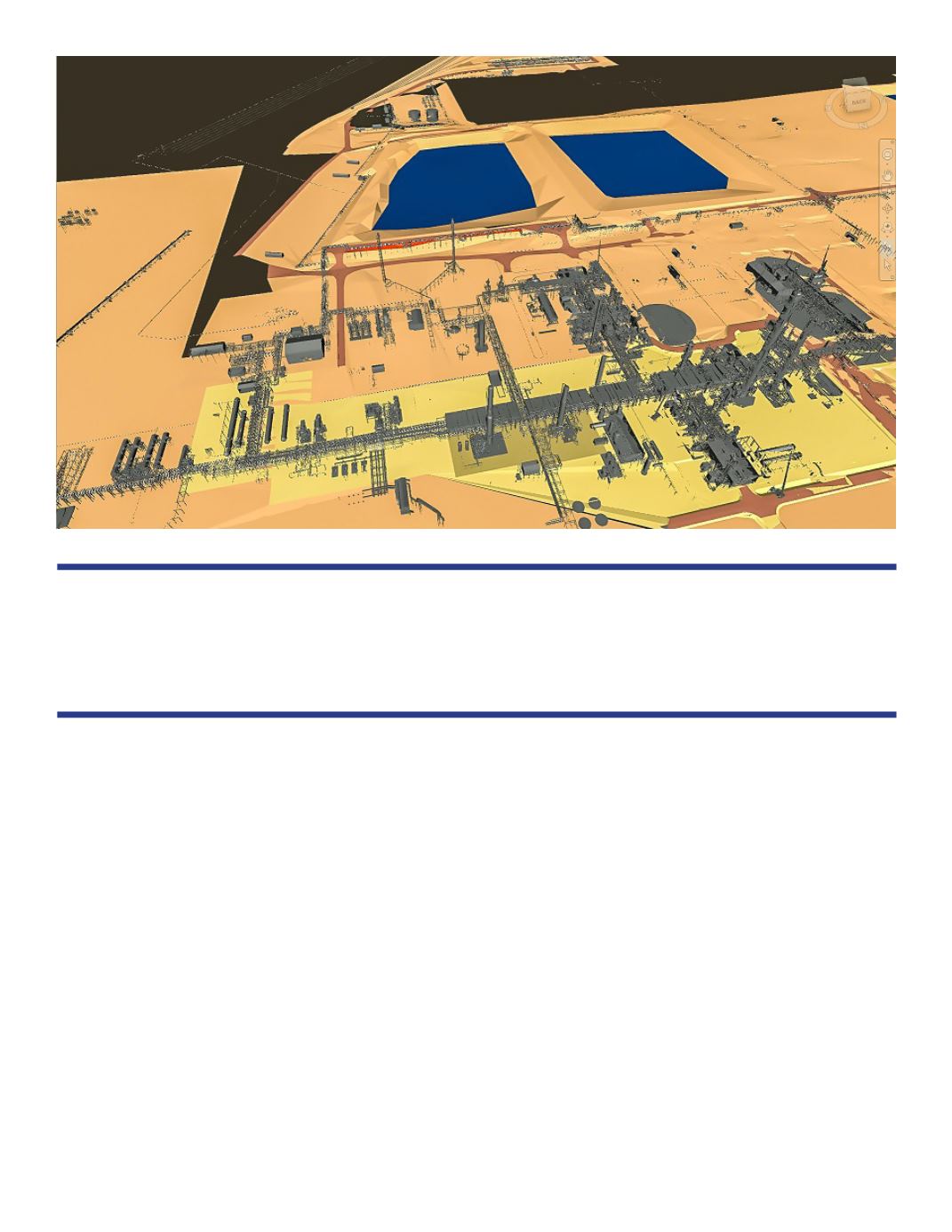

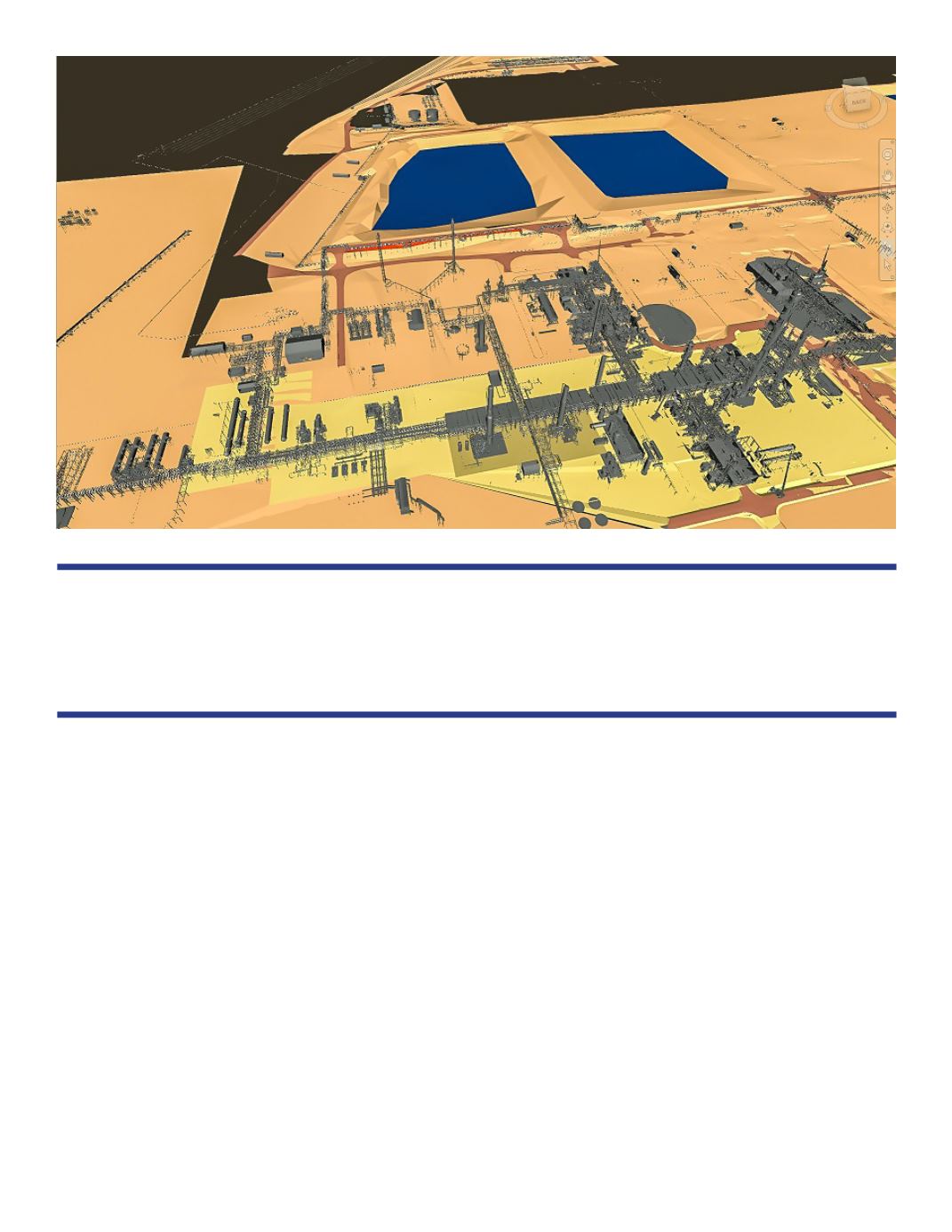

Rangeland was also involved with the

Strachan gas plant, another major facility,

which is home to a number of services

like sulphur recovery and storage. Last

fall, Rangeland worked on the Strathcona

Rail Terminal project in Edmonton, which

is one of North America’s biggest crude

oil loading sites. There are safety concerns

about transporting crude by rail, Daye said.

Due to a possibility that flammable sub-

“We were so busy here that work came to us unsolicited. It’s a whole different

world today, but we are adapting.”

JUNE 2016

H

business elite canada

7