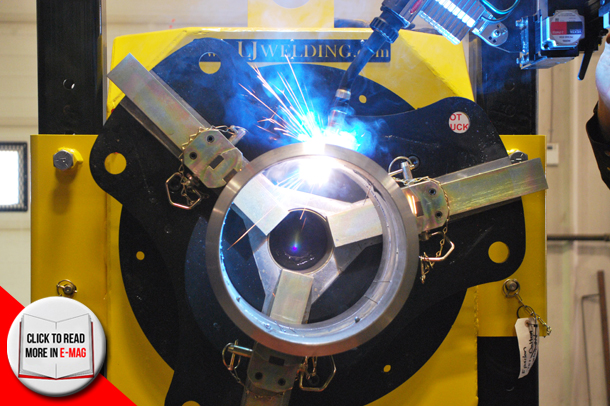

Innovative Automation that gets the job done right the first time

~ By Leah Kellar

Embracing new technology in a traditional trades industry is one important factor of LJ Welding Automation’s success. While it may be inevitable that the compound demands of technological innovation will see the competition adopt the same technologies from North America and abroad, LJ Welding prides itself on staying ahead of the curve.

“That is one of the things that separates us from other companies. We have embraced a lot of technology from various parts of the globe. Part of our strength is integrating all of these technologies together— be it a laser vision system, or a camera system, or a robotic system— we integrate all of these to what the client needs, and that reduces not only the manpower required, but introduces a measure of adequate quality control,” Adam Carpenter, President of LJ Welding Automation told Business Elite Canada.

LJ Welding is an Edmonton, Alberta-based integrated engineering and manufacturing company with worldwide expertise in top quality semi-automated and fully-automated solutions and services for the welding industry. The company predominately provides welding positioners, vessel rotators and pipe and tank turning rolls and welding automation. A sister company specializing in automated metal processing established in 2012 exists in Saskatchewan and supplies LJ Welding with all of its laser cut steel, and steel for the equipment it manufactures in Alberta. LJ Welding has a standard product line of equipment for sale and for rent.

It also has a very technologically sophisticated engineering division that sets the company apart from the competition, particularly it’s

complementary engineering, design and style work provided to international companies worldwide to solve a variety of complex problems at each stage of business. This even includes tackling subsidy issues. Carpenter highlights the importance of LJ Welding’s exceptional quality control, and how quality control requirements have risen significantly in the oil and gas industry ever since the disastrous British Petroleum oil spill of 2010 in the Gulf of Mexico.

“We are a very large part of helping to automate that quality control process,” said Carpenter with a discernable pride in his voice.

Integrated automation processes and a consequently innovative quality control system have aided in the completion of several milestone projects since 2006 for LJ Welding. Some of the most noteworthy include massive tunneling projects in South America, and subsea riser-pipe plant automation in South East Asia, and the Gulf states—one of which was for a Fortune50 company. The company that was founded in 1976, has received a number of recognitions for its well-honed system of technological integration of automation in the industry and its resulting growth, including 10th place on Alberta’s 2014 Fast Growth 50 List and winning the Alberta Manufacturing Exporter of the Year for 2013 at the Alberta Export Awards, a recognition which pays tribute to innovative approaches to exporting by Canadian companies.

Carpenter estimates that revenues have increased by almost fourteenfold since the current management took over in 2006, which is not too shabby considering that himself and the other original company partners (Ryan Holt, Tim Robinson and Brian Carpenter)admittedly didn’t quite know what they were getting into at the time of purchase. But the financial records looked good, Carpenter recalls, even at that time and consequently LJ Welding was purchased in partnership. Oddly enough, the company up then for sale by its founder, was brought to his father’s attention in conversation with his realtor at the time— and it just so happened to be a welding and machining company.

Carpenter’s career in development and sales for a technology company and his experience in financing heavy equipment prior to purchasing LJ Welding attributed to its competitive technological advantage in welding automation. He holds an educational background with a BComm in international business and management planning.

Earlier this year one of the company’s VP of Global Sales, Rob Stuart, also joined as a partner. Carpenter and a few initial co-owners, including Ryan Holt and Tim Robinson, operated and grew the company since they took over the books from founder Larry James Wesley on April 1st, 2006. Adam Carpenter’s father, , Brian Carpenter, continues to be involved with the company as a silent partner.

* As the old adage goes, the “sum is greater than its parts” and that seems to be the recipe for LJ Welding’s continued success, which is directly attributable to the different strengths of each the business partners. Each partner contributes years of expertise in engineering to stay ahead of the curve in an ever-evolving industry, while managing different areas of the business. Ryan Holt takes care of business development, management, technical sales and engineering liaison. Tim Robinson is also a critical part of running an efficient business with expertise in ?

The initial switch to new ownership and management came in advance of a new era of technological transition in the Canadian and international welding and fabrication industry—case in point being LJ Welding’s new automated cell for welding subsea riser pipe. According to what Carpenter has observed in the industry, the vast majority of companies have a relatively archaic way of accomplishing the same business requirement, and as a result measures of quality control tend to suffer. The new automated cell for subsea riser pipe is making a difference on various fronts including quality control to keep products and services ahead of the competition.

“Quality control is so important, word is now spreading. We’re not marketing it proactively, but the same company keeps another system online, then word spreads to other large companies, and that’s how it’s been working for us. So the subsea application has been working very well for us, and that’s a large trend,” said Carpenter. “The accuracy of the automated system is needed to increase quality control and to increase output. Everyone’s trying to squeeze out more with higher quality, that’s where we come in with our automated system.”

Ironically, Carpenter notes that LJ Welding is having more difficulty advancing the automation process in Alberta in the welding and fabrication industries than internationally. Most of the company’s automation success is outside of Canada.

He added that the market really demands this kind of cutting-edge innovation that has put LJ Welding among the top 10 business leaders in growth and innovation this year.

“What it means to not only myself, but to our employees, and our company as a whole, is that it’s recognition for all the hard work that we put in over the last eight years,” said Carpenter.

He also sees the recognition as an indication that LJ Welding is doing the right thing in terms of diversification after the economic boom then bust cycle of 2008-2009, which was a relatively new phenomenon for entrepreneurs and business owners just entering the markets in the early part of the past decade.

“With any different culture, you have to respect that culture and how they do business. That is important, and going in we’re always very sensitive to be respectful of differences,” said Carpenter.

One of the reasons that LJ Welding focuses on diversification and the respect for global cultures and business practices is to be able to excel in forming partnerships in various countries with its main expertise lying in welding automation for the oil and gas industry.

“Diversifying through different industries was not working for us so we decided stick to our knitting as it were and oil and gas is certainly our strong suit and we just went after the expansion on a geographical and global level and it’s been working for us extremely well,” said Carpenter. “A global focus takes the ebbs and flows out of any particular industry. If it’s slow in Alberta or Canada, it may not be slow in the Middle East for example. It has also taken out the peaks and valleys for us as far as our revenue stream and cash-flow are concerned.”

Looking to the future, growth has not slowed down for LJ Welding and has continued on the aggressive curve, which is why the company had to start construction on a new building—a 18,000 square-foot, multi-million dollar facility slate for completion in October. Within the next couple of years the company will also be opening a partnership division in Huston, Texas.

“From a logistics perspective that will give us greater access to the market in the U.S. In the next couple of years we’re just going to continue on the same growth pattern,” said Carpenter.

Carpenter credits LJ Welding’s growth, not only to it’s technological expertise and innovations in welding automation, but also simply to meeting the discriminating demands of its customers.

“Our products have always been driven by what our clients need. We don’t come up with these ideas by ourselves, it’s very much in conjunction with the problems that our clients have and seeking a solution, because they can’t find any equipment out there that exists, so our success is very much a collaborative affair in this way.”