Worldwide TIER 1.5 for the Automotive industry

By Rajitha Sivakumaran

Injection molding is the most common way of producing plastic products, playing an important role in a number of industries around the world. In fact, it is what propelled Vincent Houle, vice president of strategy and client relations at M.I. Integration, to join his parents’ company. When Sherbrooke-based M.I. Integration decided to open an injection molding facility, Houle, with a background in theatre and marketing, was immediately drawn to the family business he’d had no interest in previously joining.

This career move was a smart choice to make because the company has been growing steadily since 1984. Houle’s father was a wood modeller by trade and when he and his wife started their first company, they serviced only a single primary customer. Eventually, working with wood became less strategic for growth and in 1989, the couple started Moules Industriels with a shift towards mold injection, EPDM rubber and thermoplastics for the automobile sector.

In 1998, in response to a demand to convert metal parts into plastic components, M.I. Integration launched its thermoplastic injection division. Since the acquisition of a company called Plastech in 2002, M.I. Integration has evolved to become an all-inclusive spot for tier one companies. M.I. Integration now consists of Moules Industriels, Plastech and SLP M.I. Integración with offices in Québec and Mexico. This September, the company will be launching its mold-making facility in Mexico. Specializing in thermoplastic parts by injection in addition to manufacturing mold, M.I. Integration exclusively serves the automobile industry and has partnered with industry powerhouses like Ford, GM, Fiat-Chrysler, BMW, Mercedes, Volkswagen and Toyota.

Since he first joined the company’s sales department, Houle has been actively involved in the sales, business development and strategy aspect of things. Houle’s sister, Marie-Claude Houle, serves as the vice president of operations, which compliments her background in mechanical engineering. Even their parents continue to play a role in the company. There is a special synergy in this sibling duo that allows for the further progression of their parents’ grassroots operation. Moreover, special care is taken to ensure that the entire M.I. Integration team is on board.

“We offer an environment where everyone can develop personally and professionally inside the organization. These are the people who make us who we are today. It is important to us that the people we are working with don’t see their job as a job, but are seeing their job as a possibility to grow,” Houle said.

The innovation behind success

M.I. Integration was named one of Canada’s Best Managed Companies for 2015. Houle said that financial success was only one of the reasons behind this recognition. “We believe that we have a good strategic formula,” he added. The company has re-invented its business strategy by being more involved in design and bringing a solution into the market rather than just a part. This involvement allows M.I. Integration to market itself as a tier 1.5 company. In actuality, tier 1.5 does not exist, but this descriptor allows potential clients to see where M.I. Integration fits into the supply chain. “We want to be involved with tier one to make them shine,” Houle said.

Focusing on a specific business has also catered to the company’s success. Understanding the market and envisaging its direction play key roles in the success of any company involved in the automobile sector. In fact, there is an in-house department within M.I. Integration, designated solely to the study of the automotive market. “We created new positions in the organization, which put a lot of emphasis on understanding the market. We’re looking at the challenges specific to each car manufacturer,” Houle said, adding that the challenges faced by GM may be significantly different from those of Ford.

Understanding the automobile industry is important for business since M.I. Integration caters to clients who then directly interact with original equipment manufacturers. Offering personalized solutions to its clients is one way M.I. Integration stays ahead of competition. Paying attention to money matters also gives the company a competitive edge. “In one direction, we’re looking at improving performance for our customers and the products themselves and in the other direction, we’re always looking at the total chain cost,” Houle said.

Where there is success, there are challenges. “Our challenge is to be global to support our customers in Asia and Europe,” Houle said. The company is invested in a global growth strategy and has already started developing partnerships in Asia in order to meet customer expectations. Consequently, running a company in a different country requires adapting to its culture, which presents a challenge in the management of foreign workers and partners — something M.I. Integration has gotten a taste of since opening its branch in Mexico.

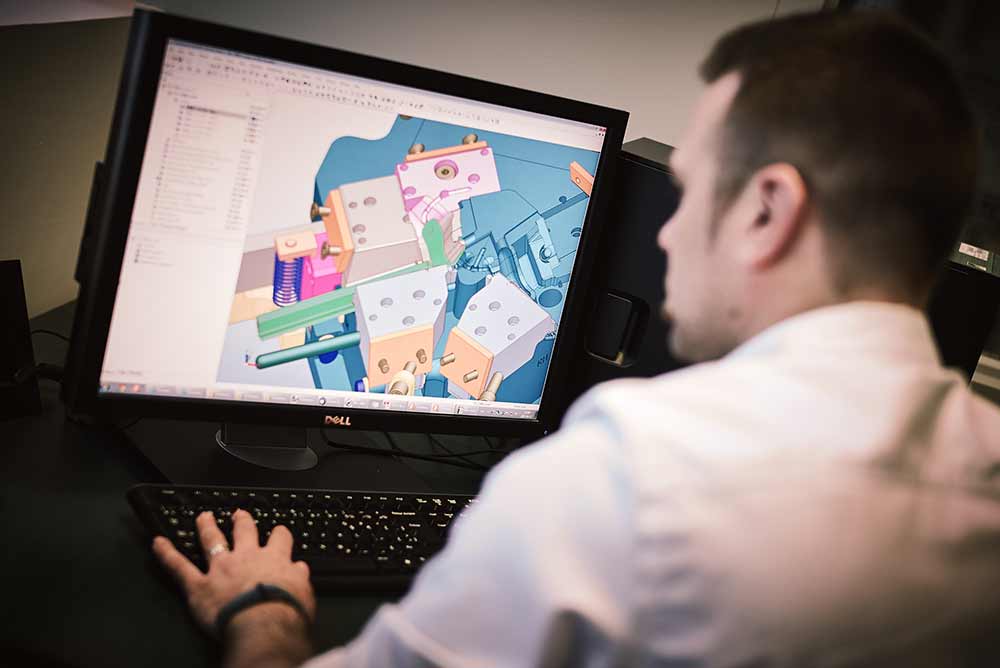

The second challenge is innovation. “We need to bring new innovation, significant innovation, every year,” Houle said. In this line of work, competition has a global extent and staying competitive means being innovative. The M.I. Lab was created for research and development. “We have dedicated people looking into implementing different technologies in our product portfolio… Our M.I. Lab is in direct connection with our customers and with the engineering team to look at different technology that could be available for the next generation of parts. That kind of service brings us great opportunities where we are the only ones to be considered for product development,” Houle said. Work done in the lab was recently awarded the prestigious ADRIQ-RCTi Innovation Prize.

The biggest trend in the automobile industry is the shift towards producing eco-friendly cars that require lightweight parts. With the amount of research that takes place in the M.I. Lab, Houle is certain that the company can find ways to bring in new technology in vehicle sealing — the part of a car the company specifically specializes in.

www.mi-integration.com