“We believe that Hifi has the potential to help the energy industry’s future and our goal of 100% safety.” —Enbridge

By Anna Guy

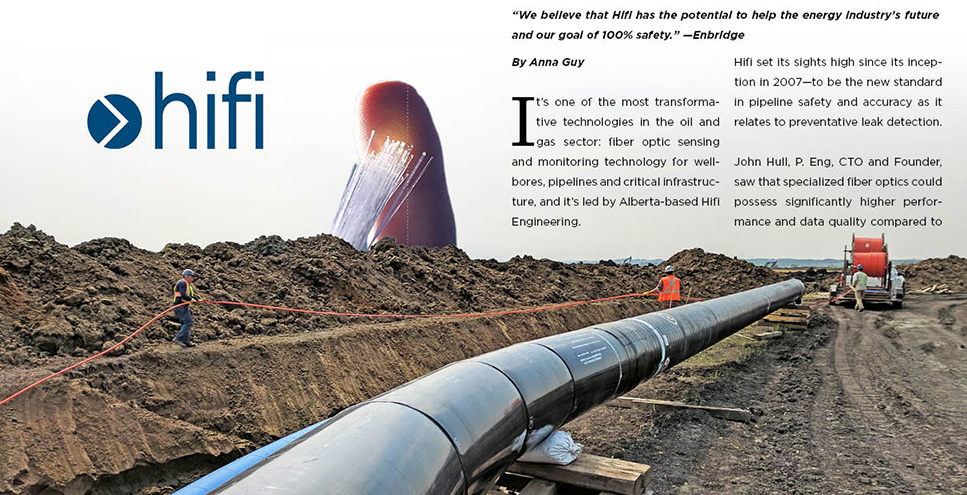

It’s one of the most transformative technologies in the oil and gas sector: fiber optic sensing and monitoring technology for wellbores, pipelines and critical infrastructure, and it’s led by Alberta-based Hifi Engineering.

Hifi set its sights high since its inception in 2007—to be the new standard in pipeline safety and accuracy as it relates to preventative leak detection.

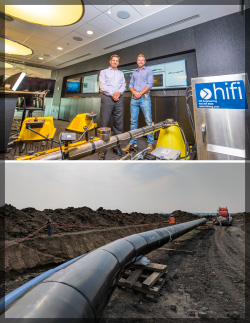

John Hull, P. Eng, CTO and Founder, saw that specialized fiber optics could possess significantly higher performance and data quality compared to first- generation fiber sensing which used standard telecommunications fiber optics. Hifi began using the technology on downhole oil and gas wells, and have proven the robustness of the technology through over 1,000 wells successfully completed. Steve Koles, President and CEO of Hifi, came to the team in 2014 bringing over 20 years of operational and executive experience in technology companies.

In 2014, both Cenovus and Enbridge made an equity investment into the company and at that time, Hifi made a strategic change to focus on pipelines with preventative pipeline leak detection. Today, Hifi has almost 30 staff, including high end electrical and software engineers with significant energy experience, almost 50 patents, and has pipeline deployments across North America with major pipeline operators including Enbridge, TransCanada, Kinder Morgan / TransMountain, Plains MidStream, ExxonMobil and Husky. A number of international deployment projects are also planned.

HIGH FIDELITY DYNAMIC SENSING (HDS)

At the core of Hifi’s technology is specialized fibre optics which produce “crisp, clear” signals from beneath layers of concrete and steel casing in the pipelines. These signals provide reliable, easy to understand, information for sensor systems for leak detection and incident prevention.

“Hifi provides a specialized and fully distributed, fiber optic sensing technology—we call it high fidelity dynamic sensing (HDS) which is highly sensitive to acoustics, temperature, vibration, and strain,” Hull explains.

HDS senses strain, vibrations or movement down to a micrometre of displacement, and for the sound of gas or liquid escaping from a pinhole leak—an impossible task with previous methods.

“By complementing conventional leak detection systems, HDS provides a solution to space and time where historical approaches may not be able to detect a leak at the right location or right time,” says Koles. “HDS senses every centimeter of the asset in high fidelity, using the speed of light on a 24×7 basis, allowing the technology to provide information back to the pipeline operator on exactly where and exactly when an event such as a leak has been detected.”

“It can be used for preventative leak detection in pipelines, by determining the exact location and the exact time of an incident such as pipeline leak, or other abnormality such as security intrusion, or a geotechnical event like an earthquake,” says Hull.

“Our integrated HDS system —which combines sound, vibration and temperature data—differentiates us from acoustic-only sensors and temperature-only sensors.”

WORLD CLASS TECHNOLOGY

Hifi is ready to showcase its HDS technology performance as indeed world class, can outperform yet complement other alternatives and traditional systems, and is ultimately ready to assist the industry in the mission critical path to improved pipeline safety

“Hifi has been included in a significant number of head-to-head performance comparisons to other technologies,” says Koles. “What differentiates HDS is its fully distributed nature optimized for long distances, it’s extremely high sensitivity, and its high alarm accuracy with the integration of acoustics, temperature and vibration/strain.”

A test conduced by C-CORE proved the Hifi HDS system successfully detected all leaks generated during this testing program, with no false positives in real time—in other words, 100 per cent accuracy.

“We believe HDS can help the industry continue to improve safety, and convince all stakeholders that more is being done in terms of investments in new innovation to support this safety.”

A lot of other people believe in Hifi, too. Not only endorsed by the biggest players in oil and gas, Hifi has been caught the attention of the Ministry of Innovation, Science and Economic Development Canada, Sustainable Development Technology Canada (SDTC), Canada’s Environment Minister, and CAPP, to name but a few organizations who are interested in Hifi’s combination of technological innovation and safety.

On track to becoming the global standard as it relates to preventative pipeline leak detection, Hifi has made tremendous progress with a number of short, high consequence area (HCA) deployments and are now supporting longer and longer pipelines which are hundreds of kilometers in length.

Koles believes innovation is what will keep Alberta’s oil and gas sector healthy. “[The sector] is well positioned to continue to be successful and a major contributor to the Canadian economy. However, with continued competitive pressures, pipeline capacity, and commodity price volatility, continuous innovation will be required to improve efficiencies, safety, and operating scale.”