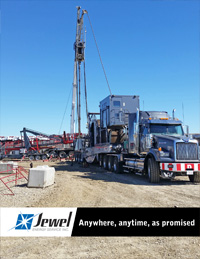

Anywhere, anytime, as promised

By Cheryl Long

Bringing the best solutions to their customers is the driving force behind Jewel Energy Service Inc. When the company had an opportunity to introduce a cloud-based tool designed to offer real-time field data as the job was being executed, they knew it was something that would bring peace of mind to their clients and innovation to the oilfield.

“We let our clients hook up with our rigs in real time and see what we’re doing out there and give them the opportunity to have a hand in the operation,” said Vern Mathison, who handles sales for the Western Canada company. “Technologically, that’s the goal of the company — to bring new and innovative ideas to the workover or completion part of the business.”

Jewel Energy was formed in April 2011, providing intermediate to heavy-duty coiled tubing and pressure pumping services to a growing market in the Western Canada Sedimentary Basin. As the business grew, they began developing a reputation as a highly-respected company where customer satisfaction and employee safety were top priorities. Three coiled tubing rigs has expanded to six and the fleet also includes heavy duty cranes and pressure pumping trucks. Their business and sales office in Calgary, Alberta, and operations base in Red Deer, Alberta, were recently joined by a full-service operations facility in Arcola, Saskatchewan.

Put simply, coiled tubing is a string of jointless steel tubing that can stretch from 1,000 to 7,500 metres in length with diameters ranging anywhere from .75 to 3.5 inches. When work is needed to be done on a high-pressure well, the tubing can be run continuously into the wellbore, keeping the well safe and under control. At that point, a variety of work can be carried out depending on the issues impacting the well. Fracturing a formation, removing sand from the wellbore, hydraulic or mechanical scale removal and setting packers are just a few of the services Jewel Energy provides. By combining engineering and planning with the best choices in equipment and technology, the company can bring significant improvements to the performance of their customers’ oil and gas wells.

Their approach to any challenge begins with engineering, combining data with a plan to safely execute work on the job site. The Jewel Energy crew has a clear understanding of the task and any possible hazards before they arrive at the customer’s location, and it’s this philosophy that ensures the most successful outcome.

For most companies, success is also synonymous with expansion. But growing too quickly is something that Jewel Energy is careful to avoid. Determined to “walk before they can run”, they’re focusing on doing the job well in a specific region, particularly Red Deer and southeast Saskatchewan, before moving west of Red Deer toward Grand Prairie, Alberta. Later, plans may eventually take them into the U.S. market.

“You don’t have to be in multiple markets to be successful,” Mathison said. “All you have to do is do what you do well in the market you’re in and then, when you’ve gotten comfortable with that, you can look to expand into other markets and go from there. You want to grow very wisely.”

Growth comes with its challenges, and one facing the industry is a lack of skilled labour. Finding people experienced in the heavy-duty coiled tubing business is difficult. It can take years for someone to acquire the knowledge needed to understand the industry’s working conditions and operate the massive rigs, and rapid growth has impacted the number of people available for hire. Fortunately for Jewel Energy, their reputation has made them a sought-after company among job seekers as well as customers.

“We’re one of the companies that people want to work for. Our guys in the field have told me they enjoy coming to work here because everybody is upbeat and very positive,” Mathison explained. “If anybody has any questions, there’s always somebody willing to take the time out to step aside and explain exactly what it is we’re doing or how it should be done.”

The company’s dedication to safety is another attraction for both employees and customers. Their Quality, Health, Safety and Environmental (QHSE) program is a key part of their operations, and they are compliant with several safety-affiliated organizations and programs including ISNetworld, ComplyWorks, COR and NSC. “Everybody always enjoys going to work for a company where safety is one of the foremost priorities,” Mathison said. Moving the heavy mobile rigs from job to job poses a different kind of challenge. Along with the difficulties that come with remote site locations, acquiring permits and working through transportation laws that vary from province to province can be time-consuming, especially when getting to the location on time is crucial.

But that’s one of the reasons Jewel Energy is enjoying steady growth. They’re recognized for their commitment to their customers and employees, and have developed strong relationships with other companies, particularly some of the area nitrogen companies since nitrogen is a key component in the coiled tubing business. “We’ll scratch each other’s backs”, letting each other know when work might be available, Mathison said.

The company has an active sales force that meets regularly with oil company executives and makes sure that Jewel Energy has a spot on the tender lists. Many jobs require bidders to go through an RFP process or become qualified as a vendor via the supply chain management system. Other customers may have specific job requirements, such as employment opportunities for aboriginal people within the bidding company.

Working with clients from the planning phase through execution is the best way to ensure operational success, followed by 24/7 support and service. “We want to be the most recognized leader in this business and we’re always striving to bring forth the best solutions for the completion or workover in the most cost-effective manner.”