By Cheryl Long

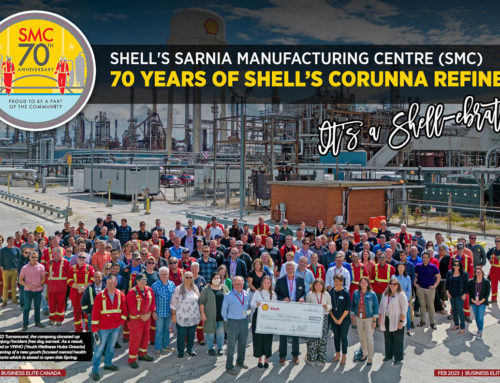

Being located more than three hours west of Ontario’s business hub hasn’t hurt Sarnia Piping Specialities (SPS). While most businesses maintain at least one address in the Greater Toronto Area, the company’s position on a major waterway in the heart of the province’s own Chemical Valley is a key part of its success.

Richard Felton is President of SPS, a family-owned business founded in 1974 by his father, Dick, who once worked as an instrument technician for Dow Chemical. The company began as a specialty piping and instrumentation distributor in Sarnia, a southwestern Ontario city known as a centre for many of the world’s largest oil and petrochemical companies. Those were the days before the internet when many products had to be shipped from England, Germany or the United States and it would take weeks before equipment arrived. SPS began by building an inventory, operating a successful “counter business” from the mid-1970s through the mid-’80s.

“Each plant in Sarnia would have a standing account and guys would line up at the counter,” Richard said. “They would come in … buy stock, buy product — that’s how they serviced their plant.” By the time Richard purchased the company from his father in 2000, the world had become substantially smaller and online ordering had changed the distribution business with its next-day deliveries, competitive pricing, and increased selection and availability.

“Each plant in Sarnia would have a standing account and guys would line up at the counter,” Richard said. “They would come in … buy stock, buy product — that’s how they serviced their plant.” By the time Richard purchased the company from his father in 2000, the world had become substantially smaller and online ordering had changed the distribution business with its next-day deliveries, competitive pricing, and increased selection and availability.

“When I bought the company, we changed as well,” he said. “Local refineries and chemical companies were laying off and were outsourcing. We went into system integration … rather than selling individual components we began supplying complete systems.”

No longer relying primarily on local refineries and chemical plants, SPS diversified and began marketing to other manufacturing industries. Today SPS is one of North America’s leading industrial solutions businesses, specializing in providing plastic-lined piping, instrumentation and safety products to a wide range of industries that includes refinery, petrochemical, pulp and paper, food and drug, power, mining, water treatment, automotive and manufacturing. They’ve evolved far beyond the days of selling equipment from behind a counter; products are just a part of the business, which now focuses on four key services: engineering, system integration, project management and maintenance.

From parts to system integration

Rather than individual parts, SPS will provide companies with sample stations as part of their system integration service, bundling products like small instrumental valves, tube fittings, pressure gauges and thermometers in one package. That service was the beginning of a company transformation from a local Ontario distributor to a Canada-wide supplier, and being part of the Sarnia business community only added credibility as SPS embarked on a period of growth.

Rather than individual parts, SPS will provide companies with sample stations as part of their system integration service, bundling products like small instrumental valves, tube fittings, pressure gauges and thermometers in one package. That service was the beginning of a company transformation from a local Ontario distributor to a Canada-wide supplier, and being part of the Sarnia business community only added credibility as SPS embarked on a period of growth.

“We were answering the marketplace,” Richard said. The increasing demand from businesses in Western Canada led to SPS opening a division in Calgary, later followed by a sales office in Laval, Quebec.

“The success of our business is because we are based in Sarnia,” Richard explained. “When customers around the world look at us and they look at our city and look at our experience, I think we win jobs because of that.”

The city’s abundance of skilled labour and expertise was a valuable selling feature when Richard first joined SPS in sales, and that reputation still offers an advantage when dealing with international businesses looking for products or services. It’s not unusual for SPS to ship orders to companies in locations like Jordan, the Dominican Republic or Singapore. And whether it’s a refinery in Russia or Saudi Arabia, there’s a level of comfort for customers who realize that SPS has built a foundation based on the needs of their industry, supplying the local petrochemical and refinery industry or hiring the people employed in these businesses.

The company’s largest demand for products and services continues to come from Canada’s oil sands region followed by the power industry. In the meantime, SPS continues to be a company that prides itself on adaptability by talking and listening to their customers, keeping up with technology and focusing on a high level of service.

“We reinvent ourselves very fast. We’ve gone from a stocking distributor to a system integrator, and the next future for business for Sarnia Piping is service,” Richard said. “Being able to provide on time, immediate service to our customers is going to be important.”

Innovative safety shower was a turning point

An increased focus on industry safety in the mid-2000s turned Sarnia Piping’s sights to new products. One of the company’s greatest successes lies in the safety shower business, spurred by American National Standards Institute (ANSI) regulations that now prevent companies from using cold water in their employee safety showers. In 2009, ANSI changed the standard to ensure shower water was a tepid 60 to 100 degrees Fahrenheit, and that quickly became a challenge for large, older plants that didn’t have an easy way to heat water running to the showers.

An increased focus on industry safety in the mid-2000s turned Sarnia Piping’s sights to new products. One of the company’s greatest successes lies in the safety shower business, spurred by American National Standards Institute (ANSI) regulations that now prevent companies from using cold water in their employee safety showers. In 2009, ANSI changed the standard to ensure shower water was a tepid 60 to 100 degrees Fahrenheit, and that quickly became a challenge for large, older plants that didn’t have an easy way to heat water running to the showers.

In response, SPS launched a joint venture with England-based Hughes Safety Showers to provide unique tank showers outfitted with immersion heaters and self-contained tepid water tanks. Hughes Safety Showers North America in Sarnia has been a substantial contributor to the growth of SPS, and customer response to the product has been impressive.

Part of the SPS success story can be attributed to the company’s employees, many with 15 or 20 years of service. That sense of history and level of experience has helped to solidify the company’s reputation as one of integrity and reliability.

“I have a great staff. That’s our other secret to success,” Richard said. “You’d be hard-pressed to walk through this office and figure out who owns the company. By talking to the people, you would think we all own the company. I think we respect our people. We see the value in them and we know that we’re not a company without them.”

New technology has customers in mind

Future growth for SPS is going to come with changes in technology, whether it’s the company’s new ERP system, plans for an updated website or the setup of an online portal that will allow customers to place and review orders, or track down invoices. “As a small company with 12 employees, we have an IT department and a computer system like a Fortune 500 company,” Richard said. They’re also focused on finding that next specialty product that will provide solutions for their customers similarly to the success of the safety shower.

“I think we’re at a point where we do need to make a decision. Are we going to be a niche speciality-type supplier or are we going to be that all-in-one, one-stop shopping supplier?” Richard explained. “I think that’s where I see us going in the next five years, spending a lot of time writing business plans and looking to the future to see what customers are going to need.

“Overall, I think it’s going to come down to service and communication with the client, being able to service the products we sell, being able to go onsite and fix or provide recommendations to the products they already have.”

To learn more about Sarnia Piping Specialities, visit spssales.com.