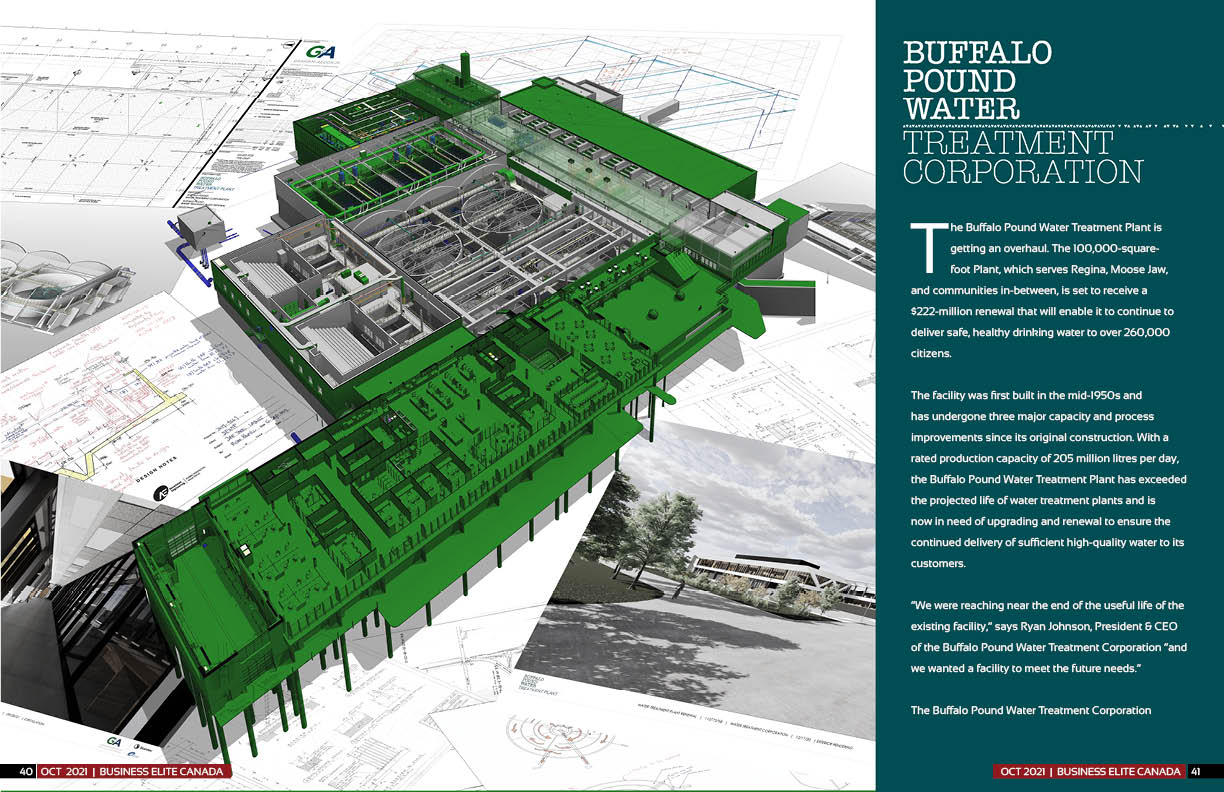

The Buffalo Pound Water Treatment Plant is getting an overhaul. The 100,000-square-foot Plant, which serves Regina, Moose Jaw, and communities in-between, is set to receive a $222-million renewal that will enable it to continue to deliver safe, healthy drinking water to over 260,000 citizens.

The facility was first built in the mid-1950s and has undergone three major capacity and process improvements since its original construction. With a rated production capacity of 205 million litres per day, the Buffalo Pound Water Treatment Plant has exceeded the projected life of water treatment plants and is now in need of upgrading and renewal to ensure the continued delivery of sufficient high-quality water to its customers.

“We were reaching near the end of the useful life of the existing facility,” says Ryan Johnson, President & CEO of the Buffalo Pound Water Treatment Corporation “and we wanted a facility to meet the future needs.”

The Buffalo Pound Water Treatment Corporation was established in January 2016, through the Unanimous Membership Agreement by the Cities of Regina and Moose Jaw, which have jointly owned the Plant since 1955.

“Our mandate is to ensure that the Plant is able to operate without problems into the future,” says Johnson.

Progressive Design Build Format

One of the pioneers in the use of the GAC (Granular Activated Carbon) filtration process for the removal of algae-produced taste and odour, the plant is now pioneering a new progressive design build procurement format—and is the first water project in Canada to use this method.

The design services, which have been awarded for the Plant Renewal Project, are a part of a Joint Venture comprising of Graham Infrastructure Inc. and AECON Water Infrastructure Inc. as the Project leads, with Stantec & Associated Engineering providing the design services.

“Our initial decision was whether we built a brand-new facility or do a major rehabilitation,” says Johnson. “Cost-wise, there wasn’t a clear winner and we wanted the market to decide and we evaluate the submissions for the best value.” Johnson says another interesting finding came when researching procurement models in that the progressive design build was “actually the most advantageous.”

Johnson says that at the end of the day, progressive design build resulted in being the process that gives more control over the cost outcomes, because of the integrative nature of the process and the collaboration between management team, engineer team, and the contractor.

“They’ve been at the table since Day One—there’ll be minimal risk based on this process because we’ve all been able to talk about the same thing from the start,” he says. “It’s an open-book process. We know all of their costs and fees right up front.”

The $222-million cost for the Project is being funded by the Federal and Provincial governments and the Corporation (through water rates charged to its customers), with work to commence in 2022. Upon completion in 2025, the facility will be equipped to deal with the increasing challenges faced in treating the lake water and will ensure the Plant can meet current and future regulatory requirements. It will also help to ensure the long-term viability of the Buffalo Pound Water Treatment Plant as well as to ensure a reliable supply of potable water long into the future, supporting both economic development and the growth of the Cities and communities- in the region.

The technology will be upgraded considerably, including the addition of ozonation, and the conversion of the clarifiers to dissolved air flotation, and granular activated carbon contactors to biological for instance,” says Johnson. “We want to be able to ensure the plan meets the needs and supports the growth of the Cities for the next 25 years.”