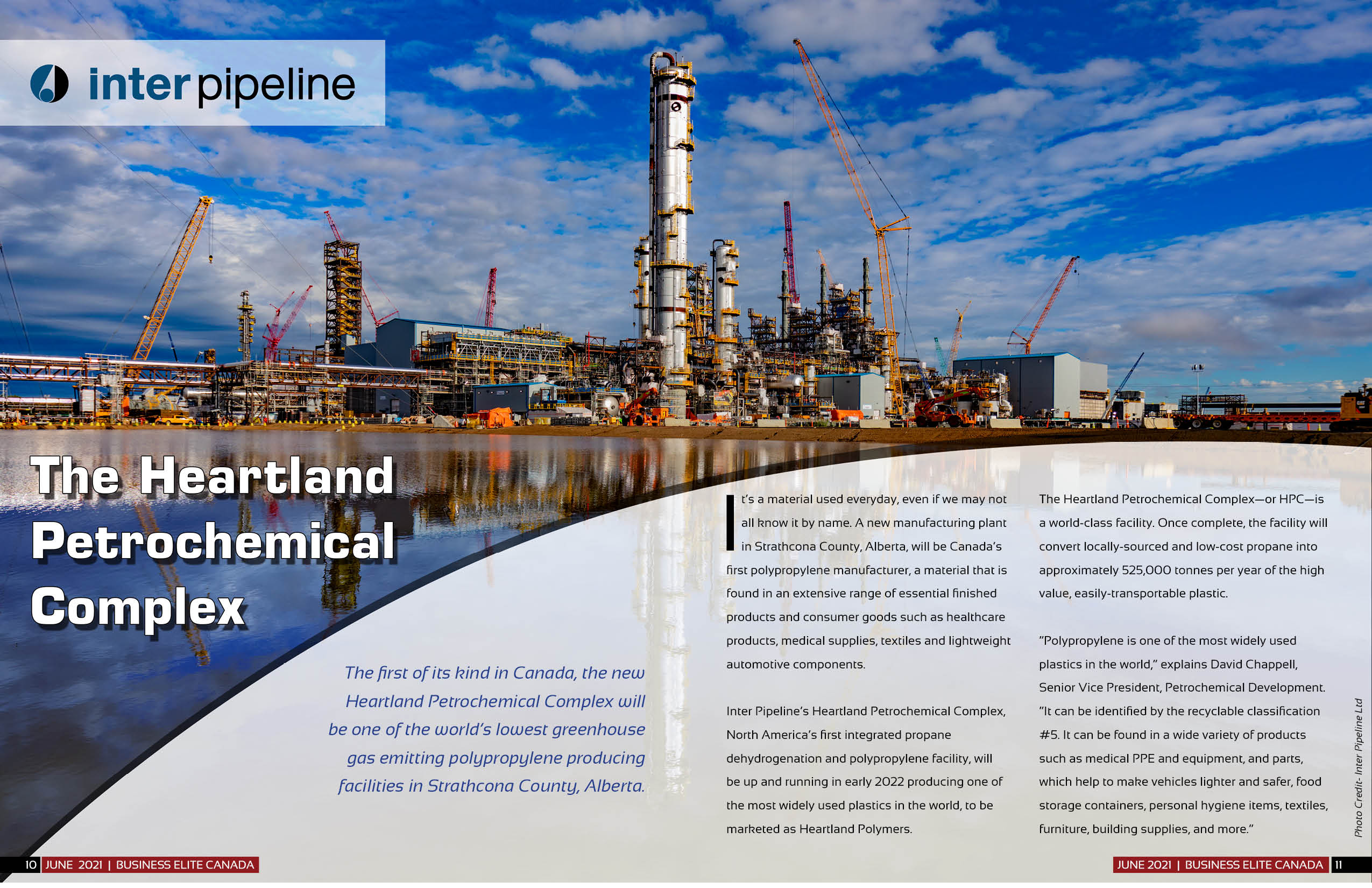

The Heartland Petrochemical Complex

It’s a material used everyday, even if we may not all know it by name. A new manufacturing plant in Strathcona County, Alberta, will be Canada’s first polypropylene manufacturer, a material that is found in an extensive range of essential finished products and consumer goods such as healthcare products, medical supplies, textiles and lightweight automotive components.

Inter Pipeline’s Heartland Petrochemical Complex, North America’s first integrated propane dehydrogenation and polypropylene facility, will be up and running in early 2022 producing one of the most widely used plastics in the world, to be marketed as Heartland Polymers.

The Heartland Petrochemical Complex—or HPC—is a world-class facility. Once complete, the facility will convert locally-sourced and low-cost propane into approximately 525,000 tonnes per year of the high value, easily-transportable plastic.

“Polypropylene is one of the most widely used plastics in the world,” explains David Chappell, Senior Vice President, Petrochemical Development. “It can be identified by the recyclable classification #5. It can be found in a wide variety of products such as medical PPE and equipment, and parts, which help to make vehicles lighter and safer, food storage containers, personal hygiene items, textiles, furniture, building supplies, and more.”

A Great Thing

Canada is in an advantageous position to create polypropylene. Propane—the ingredient needed for polypropylene—is abundant in Canada and cheaper than in the US, and Alberta is much less prone to dramatic weather shutdowns due to hurricanes or this winter’s big Texas snow storm than the nearest alternative – the US Gulf Coast.

“In Canada we don’t produce polypropylene at all,” says Chappell. “We import about 500 to 550 kilo-tonnes a year, almost all of it from the US. That happens to be the same amount the HPC will produce.”

“In Canada, we produce raw resources (in this case, propane), then we normally ship them down to the US. They turn it into polypropylene, and then we buy back for 4 to 5 times the initial value. So, we are breaking that model with this, because we are making it here as opposed to shipping an awful lot of products around. A great thing to do here in Canada.”

Polypropylene comes in three types—impact copolymer, random copolymer, and homopolymer. Chappell explains that the HPC will be producing homopolymer initially with random copolymer to follow. With the impressive sustainability focus of HPC, polypropylene produced at the HPC will help manufacturers meet growing demand as consumers seek products with increased sustainability.

“With our unique commercial arrangements, we are sharing some of the higher value petrochemical value chain with the propane producers and the polypropylene consumers,” says Chappell. “HPC capacity is currently approximately 60 percent contracted, and we are well on our way to meeting our goal of entering service with at least 70 percent of the capacity contracted.”

Position in the Market

“You want to keep operating costs low as possible, which is a model we’re following at the HPC. Our facility has one of the lowest costs for polypropylene production in the world,” says Chappell.

How did it get there?

Inter Pipeline’s off-gas business produces propane and propylene—in fact, it’s the only producer of polymer-grade propylene in Canada. “Because of that business and all the propane that we produce at our Cochrane Extraction Plant, we understand both the propane and the propylene markets, and saw there was a surplus of propane and a shortage of propylene looming,” says Chappell. “We decided this makes sense, and then we discovered we actually have a competitive advantage in transporting our polypropylene.”

There is also a strong geographic impetus for the HPC. Roughly 45 percent of North America’s polypropylene production is consumed in the US Midwest, and Canada’s competitive rail rates and range of routes to get into the Chicago region is a huge advantage for the HPC. In fact, because most of the polypropylene in the US is produced in the US Gulf coast, it is the same or a lesser price to ship into that region from Alberta as it is from the Gulf Coast.

“Our location is also favourable because we are not in a region that stops productions due to hurricanes and we are built for such extremes as colder weather,” says Chappell.

The plant itself is fueled off natural gas, which is significantly cheaper in Alberta than it is in the US, providing an advantage to its competitors south of the border.

“Additionally, we are building world-scale plants and because of that we get economies of scale,” adds Chappell.

Lastly, HPC benefits from good government incentives. “You add all that together and we are some of the lowest cost producers of polypropylene in the world, which is where you want to be when you are in manufacturing.”

Reliability

Reliability is not just about technology and design; it’s also about people. Chappell says, “We have been able to hire the best people in the industry. It’s a new and exciting business and some of the best people in their field wanted to come join our group. From engineers to construction to the safety experts, and that brings in additional knowledge and some additional dependability.”

“The market is really looking forward to our production coming online because of Inter Pipeline’s reputation for service reliability and because of the need to diversify.”

Low Greenhouse Gas Emissions

Inter Pipeline is committed to building a sustainable future through its business practices, and the HPC has been designed to deliver to shareholders the benefit of sustainability as a commercial opportunity. Through the use of advanced technology and on-site hydrogen-augmented power and utilities generation, the polypropylene produced at HPC is anticipated to have a greenhouse gas emissions footprint 65 percent lower than the global average.

In fact, HPC is expected to have among the lowest GHG emissions profiles of any comparable integrated facility in the world, making its production desirable by sustainability-minded global polypropylene consumers.

“This is something we are very proud of,” says Chappell.

Creating Opportunity

Chappell says that it is exciting to be a part of a company that is driving forward with such a significant project which adds value to a raw resource, and turns a low-value product into a high-value one – creating jobs and generating revenue in the process.

“This project is creating a lot of opportunity for people, a lot of value for Inter Pipeline and our contracted partners, and it is great to be a part of a business that is forward-thinking in its approach to sustainability.”

The Heartland Complex was designed with sustainability as a key aspect of procurement and engineering. As a result, the HPC is expected to be one of the lowest greenhouse gas emitting facilities, per tonne of polypropylene produced, in the world.

“It’s also exciting to be partnering with great organizations like Women Building Futures (WBF) to help create opportunities for women to get high-quality job experience in the skilled trades, and with the North American Institute for Technology (NAIT) on a $10 million initiative to research and identify opportunities to prevent plastic waste from entering in the environment. It’s all part of what we call the circular economy, where plastic waste is utilized as a resource instead of a disposable.”

Major Boost to Alberta

Contributing more than just polypropylene, the HPC will be a major boost to the Alberta economy. Once in service, Inter Pipeline anticipates HPC will create over 1,000 direct and indirect full-time jobs, as well as providing provincial and municipal governments with nearly $50 million in annual tax revenue to support schools, roads, hospitals and other public services and infrastructure.

Contracting and procuring locally throughout construction of the HPC has brought significant benefits to the project, including superior service, quality, timeliness and lower risk of damage to components during shipping. This locally-focused approach has been especially beneficial in the COVID-19 environment, due to the safety and logistical challenges the pandemic has created.

In April, 2021, it was announced that $408 million will be granted to the HPC under the Alberta Petrochemicals Incentive Program in recognition to the significant contribution the HPC has and will continue to make to the Alberta economy.

“HPC’s construction has created thousands of well-paid technical, manufacturing and construction jobs over its multi-year build and has been a symbol of hope during difficult economic times for the Province,” says Christian Bayle, Inter Pipeline’s President and CEO. “In total we expect that roughly $3 billion or three quarters of the project construction spend will be invested directly into materials and services provided by Alberta businesses.”

“Furthermore, we expect HPC to generate hundreds of permanent high-quality full-time jobs and substantial ongoing tax revenue for government. We appreciate the Government of Alberta’s support of HPC, and we believe it sends a clear message to the international investment community—future large-scale petrochemical investments are welcome in Alberta.”

“The Government of Alberta is proud to see the first successful application approved through the Alberta Petrochemicals Incentive Program. Projects like this are exactly what the province needs to become a global centre of excellence in the growing petrochemical sector,” said the Honorable Dale Nally, Alberta’s Associate Minister of Natural Gas and Electricity.

“Programs like APIP are critical not only for sustaining Alberta’s economy but for creating future growth,” said Andy Brooks, President and Chief Executive Officer of Waiward Industrial Management Services, one of Western Canada’s largest construction companies and a key partner in the fabrication of materials used in the construction of the HPC. “At a time when investment is truly needed, this program helps keep tax-paying Albertans working and putting food on the table, while also securing a strong future for Alberta with an exponential payback for taxpayers.”

Inter Pipeline expects to have invested approximately $4.2 billion into the project by the time it’s complete. On average over the past few years, there has been more than 3,000 men and women working on the project daily, and they have laid enough piping and steel to stretch from the plant’s site in Central Alberta to the Pacific coast.

Since inception, more than 150 Alberta businesses have contributed to the construction of the HPC. In addition, over the roughly four-year construction period, Inter Pipeline estimates the HPC will have created approximately 16,000 direct and indirect full-time jobs, generated approximately $200 million of tax revenue for provincial and municipal governments, and will have added approximately $3 billion directly to the Alberta economy.

We look forward to following up on the HPC when it is fully online in 2022.

For more information, please visit www.interpipeline.com

*At the time of publication, Inter Pipeline was undergoing a strategic review process in response to a hostile takeover bid from Brookfield Infrastructure Partners, and as of June 1, 2021 IPL had entered into an arrangement agreement for Pembina Pipeline Corporation to acquire all of the issued and outstanding shares of Inter Pipeline.