The Region of Waterloo is using innovative green technology to deliver a significant project in alignment with its environmental stewardship goals for the environment and climate action.

Waterloo’s Cogeneration Facilities capture 100 per cent of its biogas and convert it to green energy to power the plant’s electricity and heating needs—saving approximately $1.5 million per year in utility costs. In return, they will also reduce approximately 1,900 tonnes of carbon dioxide emissions annually.

The project started in 2016, when the Region of Waterloo was in the process of updating their Biosolids Strategy which looked at long term sustainable solutions for managing the solids generated at thirteen wastewater treatment plants (WWTPs).

“Biogas is the end product from this solids treatment process,” says Pam Law, Manager, Engineering and Planning at Region of Waterloo. “At the time this biogas was used onsite in boilers to produce heat for plant processes as well as buildings on site. When heating was not required, the biogas was flared off. The Region identified that there must be a way to use this renewable resource more effectively”.

In parallel to the Biosolids Strategy, the Region started a feasibility study to look at opportunities for fully utilizing this renewable gas. This aligned with a number of Regional priorities including the Corporate Energy Plan, Sustainability Strategy and Strategic Plan. In addition, with electricity prices increasing, the Region was also interested in looking for opportunities to make operating costs more sustainable, says Law.

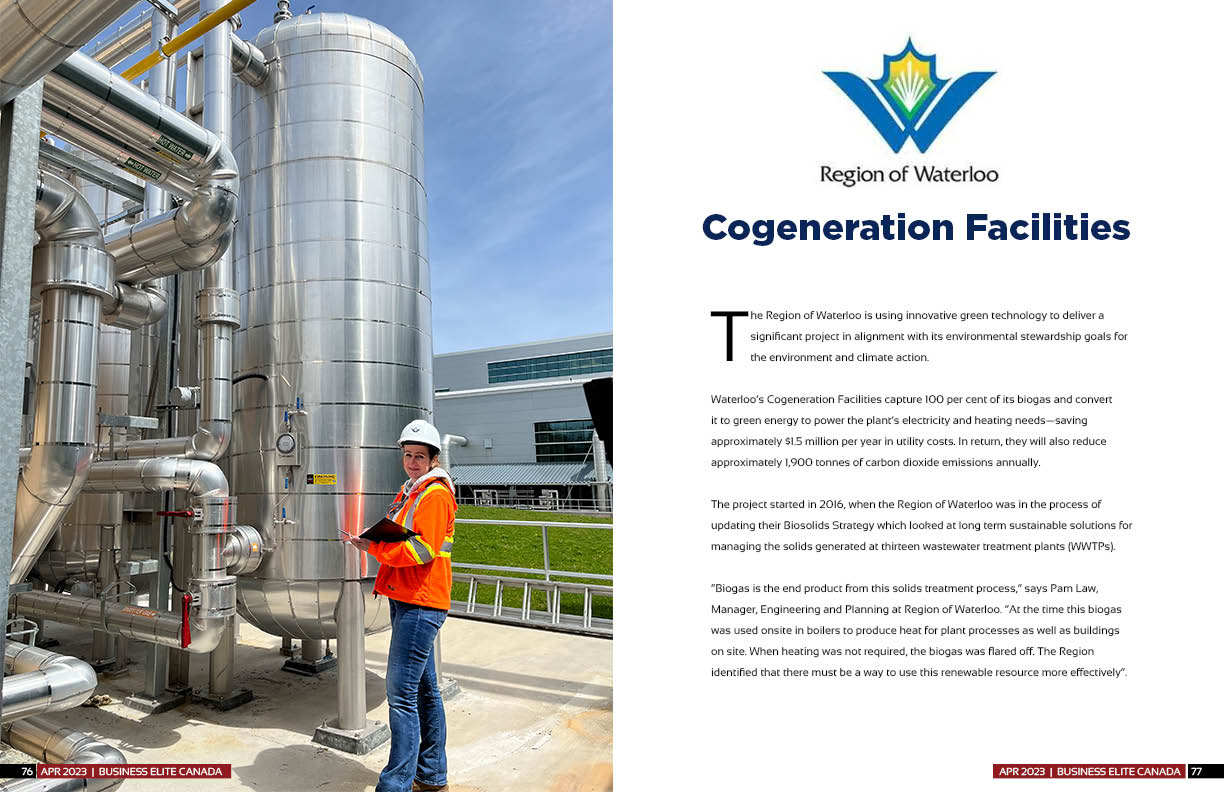

The solution came in the form of cogeneration facilities at the region’s three largest WWTPs, Kitchener, Waterloo, and Galt. “The operation of these engines allows us to meet the heating needs for our treatment processes as well as heating for our administration facilities,” says Law. “The operation of the engines also generates electricity and allows the Region to significantly displace the amount of electricity purchased from the grid.”

At the beginning of the process, the Region reached out to other municipalities that had recently implemented similar technologies, such as Chatham-Kent, the City of Toronto and the Region of Peel. “It is great to learn from experiences of other municipalities on all aspects of the process from approvals to design to operation,” says Law.

Recognized with an Award of Excellence at the 2022 Canadian Consulting Engineering Awards, the three facilities are estimated to reduce green house gas emissions at each plant by approximately 20 per cent by offsetting approximately 550 tonnes of CO2 per year during the first year of operation compared to current operating conditions. This is anticipated to increase to a reduction of 2,200 tCO2 in 2041 as the biogas volumes increase and the supplemental gas decreases, as compared to current operating practices.

The engines have been operating for approximately one year. During this first year of operation the Region was able to offset approximately $1.7M in electrical costs with the operation of the three engines, or between 30 and 50 per cent of the electricity costs at each WWTP. The Region is still working on optimizing the operation of the engines and expects in the subsequent years to offset between 50 and 80 per cent of electricity costs.

The Region took a unique approach to the design of the three cogeneration facilities. “Cogeneration engines are often sized based on biogas availability when the units are initially commissioned,” says Law. “As populations grow, wastewater and associated biogas quantity increases. The ability to fully utilize the available biogas over the 20-year anticipated lifespan of the engines is limited. The project team analyzed scenarios to select the best approach to use the most of this available resource.”

The recommendation was to size the engines based on the anticipated gas flows over the 20-year operating period, says Law. “The operation of these engines will be achieved with the installation of dual fuel cogeneration engines, which allow engines to operate with a blend of biogas and natural gas. The approach of using dual fuel engines allows the Region to fully utilize all of the biogas produced by the wastewater treatment process through the full life cycle of the engines.”

For more information, please visit www.regionofwaterloo.ca