Page 10 - Steelcon

P. 10

well-established record of success with SIN Beam

projects in Canada, Steelcon intends to build on this

SIN Beam provides our clients with the

foundation in the US.

following benefits:

• Up to 30% lighter

The development of a composite floor panel system

• Cost effective

that takes advantage of SIN Beam’s sinusoidal

• Overall large tonnage savings

profile to provide a cost-effective solution for mid/

• Expedited delivery

high rise projects is also on the top of the list for the

• Guaranteed quality

team’s R&D department.

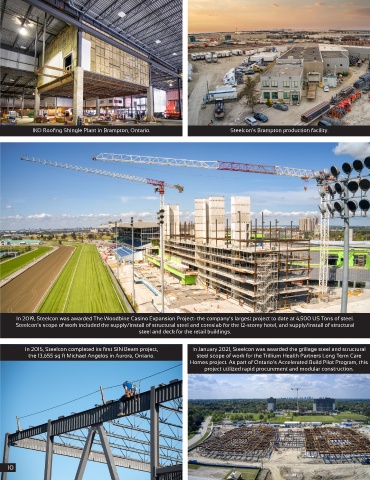

IKO Roofing Shingle Plant in Brampton, Ontario. Steelcon’s Brampton production facility. • Flexibility on member sizing and ordering -

utilizes plates and coils

And of course, sustainability is always top of mind,

• Reduced risk in case of design changes after

says Bianco. “We are fully engaged in energy

steel is ordered

modelling with the goal of creating green production

• Early involvement in design improves overall

facilities with reduced energy consumption and

savings and efficiency

sustainable operations,” says Bianco. “We know the

• LEED compliant - locally sourced material

transition to net zero is a shared responsibility, so

we are constantly questioning how we can advance To that end, our Research and Development

and accelerate the transition in not just the steel/ department is also working on a project to

building materials industry, but the construction determine the reduced carbon impact of a SIN Beam

industry as a whole.” designed structure vs a conventionally designed

structure and investigating further decarbonization

strategies and opportunities to lower

the emissions of a SIN Beam designed

structure to make it truly carbon neutral.

In 2019, Steelcon was awarded The Woodbine Casino Expansion Project- the company’s largest project to date at 4,500 US Tons of steel.

Steelcon’s scope of work included the supply/install of structural steel and coreslab for the 12-storey hotel, and supply/install of structural The next step would be to embark on an

steel and deck for the retail buildings.

initiative to educate owners, designers

In 2015, Steelcon completed its first SIN Beam project, In January 2021, Steelcon was awarded the grillage steel and structural

the 13,655 sq ft Michael Angelos in Aurora, Ontario. steel scope of work for the Trillium Health Partners Long Term Care and general contractors about the ability

Homes project. As part of Ontario’s Accelerated Build Pilot Program, this

project utilized rapid procurement and modular construction. to achieve early and significant carbon

reduction through the use of SIN Beam

design.

For more information, please visit

www.steelcon.ca

The SIN Beam designed, two-level grillage structure that supports the

modular, multi-story Trillium Health Partners Long Term Care Homes above.

10 11