of aerostructure businesses where MHI

Canada Aerospace could act as a catalyst

for a “build-in-country Canadian aerospace

strategy,” he added.

BUSINESS INCORPORATED

IN 2006

It’s a bit of a leap from the company’s early

days when a group of local independent

contractors established a working party to

help Bombardier with the final completion

of products manufactured and shipped

from Japan. In 2006, the group incorporat-

ed as a business in Ontario and the follow-

ing year, they moved into a 90,000-square-

foot facility in Mississauga and became

responsible for the final assembly work

on product supplied by MHI Japan prior to

its delivery to Bombardier. That same year,

work increased as the Challenger 300

wing assembly was transferred to Canada.

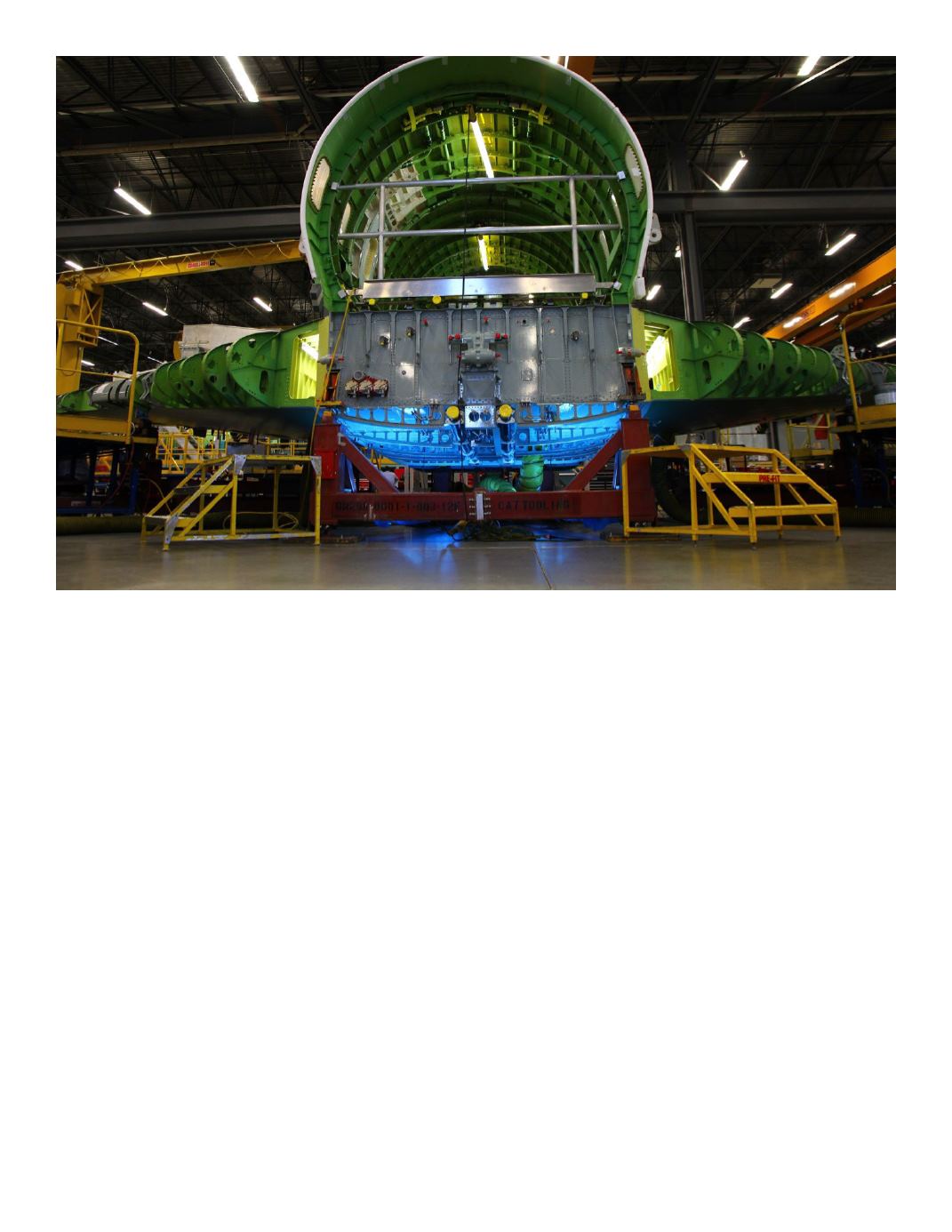

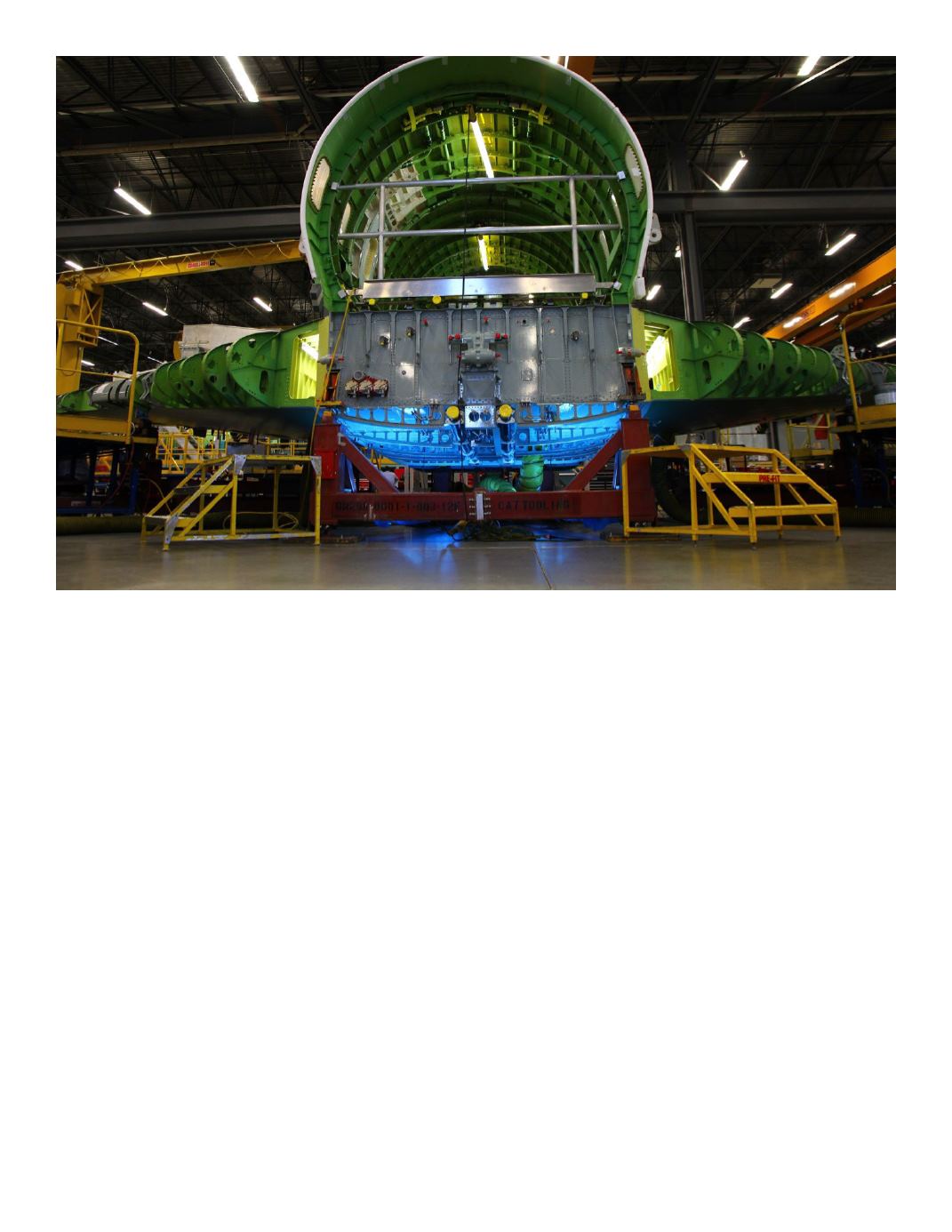

In 2012, MHI tripled its space when it ac-

quired a 270,000-square-foot facility, trig-

gering the transfer of the Global 5000/6000

wing assembly to Mississauga. They also

took on local parts fabrication for both the

Challenger and Global wings and, the next

year, opened a supply chain and logistics

centre.

McCarthy joined MHI Canada Aerospace

in April 2013 as Vice President, Opera-

tions, bringing extensive experience in

the aerospace industry. “I began my ca-

reer in the aerospace industry with Mc-

36 business elite canada

H

FEBRUARY 2017