sequently, the copper electrodes wear out

quickly under high temperatures.

“What I saw in Germany when I was with

Magna International was that this Canadi-

an company called Huys Industries had ac-

tually come up with this clever idea of put-

ting a material on the ends of the copper

electrodes, which was titanium carbide,”

Scotchmer said.

Carbides are very hard and titanium has a

high melting temperature. These traits are

opposite those of copper, making them

dissimilar metals. Generally speaking, the

two cannot be welded together since by

the time titanium carbide starts melting,

the copper has already vapourized. Some-

how, Huys accomplished this seemingly

impossible task. The result was this: the

copper electrodes lasted two to four times

longer.

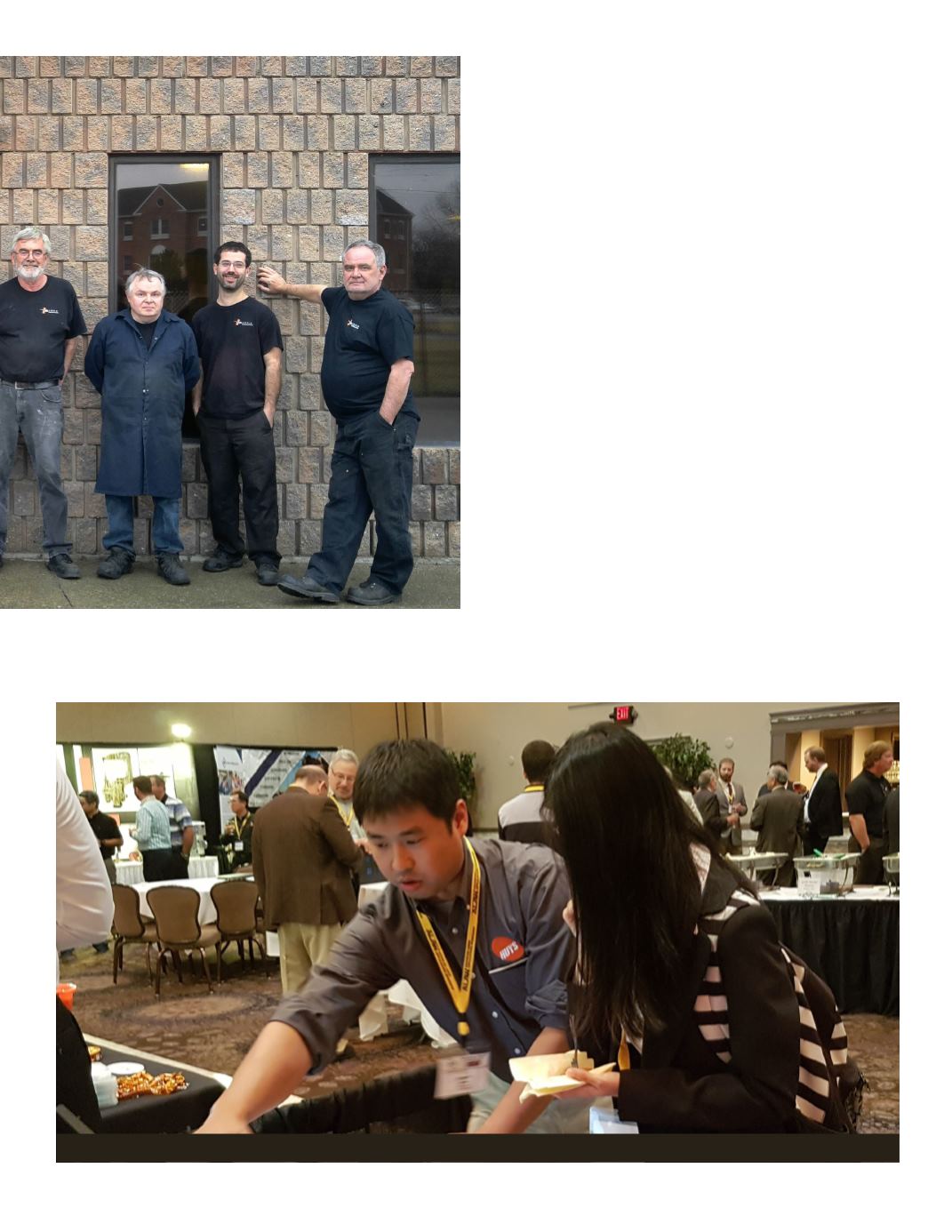

Kevin Chan, VP of Technical Sales, demonstrates the power of SORPAS simulation software

MARCH 2017

H

business elite canada 57